Why integrate Biomass Crops into Agroforestry Systems?

Key messages:

- One promising dimension in agroforestry that is yet to realise its full potential is the integration of biomass crops.

- The deliberate incorporation of biomass crops into agroforestry systems can deliver a wide range of environmental benefits including improving soil health, carbon sequestration, enhancing biodiversity, and improving water quality.

- There is the need for policies and funding provisions to support integration of biomass crops in agroforestry systems.

Introduction

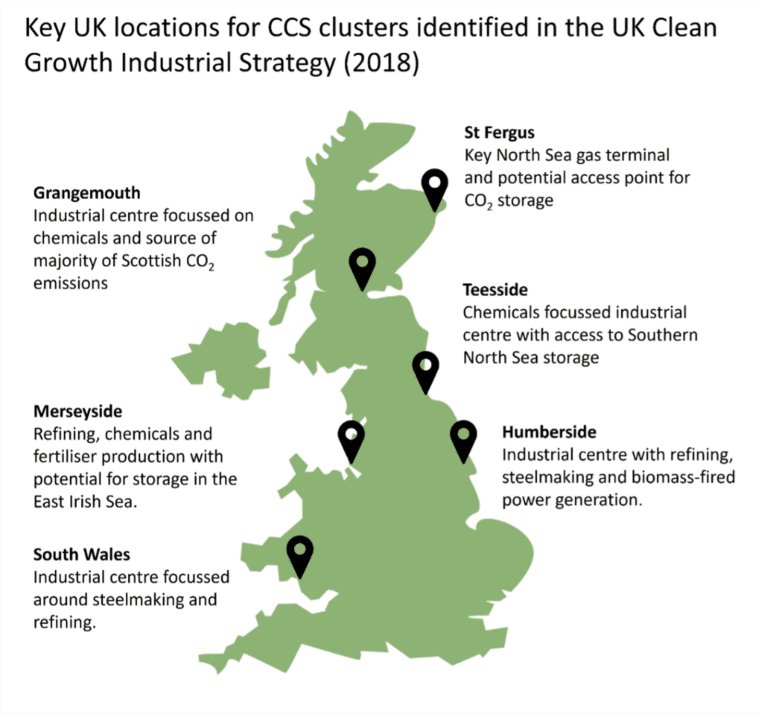

The UK government has made a commitment to achieve net-zero greenhouse gas emissions by 2050. As part of a comprehensive strategy addressing the effects of climate change, tree planting is a key component. The UK government has outlined an ambitious 25-year plan to improve the environment. This aims for a 12% tree cover by 2060, which will involve the planting of 180,000 hectares of trees by the end of 2042. In Wales, farmers are expected to allocate at least 10% of their land to tree cover in return for payments from the (currently delayed) Sustainable Farming Scheme (SFS). The Scottish government has similarly set targets to achieve a 21% forest and woodland cover by 2032, with a strong desire for greater integration of land use practices. Northern Ireland’s forest for our future programme aims to plant 9,000 hectares of new woodland (18 million trees) by 2030. To reach these goals, agroforestry can play a key role. To reach these goals, agroforestry will play a key role. Agroforestry is a land management approach that combines trees and shrubs with crop and livestock farming systems.

One promising dimension in agroforestry that is yet to realise its full potential is the integration of biomass crops (such as willow, poplar, alder, and black locust). When incorporated into agroforestry systems, biomass crops contribute in various ways, including, support for pollinator populations, biodiversity enhancement, flood risk reduction, minimized runoff and soil erosion, improved water quality, increased soil carbon sequestration, improved soil health and climate change mitigation. Moreover, they offer biomass for use as timber, wood fuel, bedding, and fodder. Despite these substantial benefits, the integration of biomass crops into agroforestry remains underexplored, with limited available information. This article focuses on the benefits of deliberate integration of biomass crops into agroforestry system.

Understanding Agroforestry Systems

Agroforestry is a deliberate practice that involves integrating woody vegetation, such as trees and shrubs, with agricultural and animal production systems to benefit from the resulting ecological and economic interactions. This can involve integrating livestock and crops into tree-only systems, as well as incorporating trees into farming systems that have crop, livestock, and mixed farms. There are five distinct types of agroforestry,including;

- Silvopastoral agroforestry, which combines trees with livestock.

- Silvoarable agroforestry, the combination of trees and crops.

- Hedgerows, shelterbelts, and riparian buffer strips, which entail growing trees between parcels of land.

- Forest farming, where crops are cultivated within a forest environment.

- Home gardens, characterized by the combination of trees and food production in proximity to households.

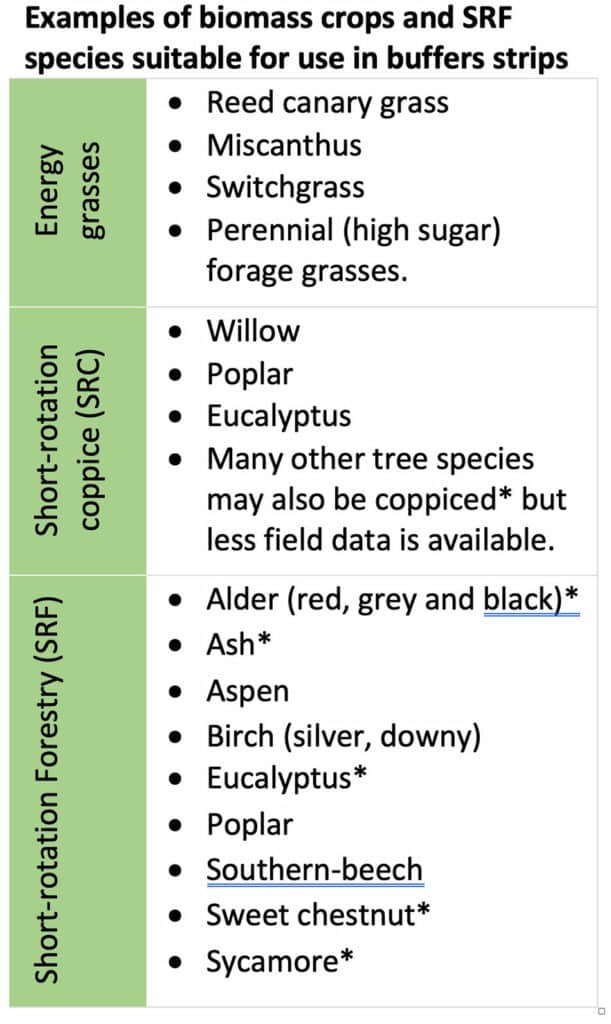

The tree component of agroforestry can be from a diverse range of tree and shrub species, including biomass tree crops (both short rotation forestry (SRF) and short rotation coppice (SRC)) integrated into existing landscapes. For instance, in silvoarable agroforestry, one might find combinations of poplar trees with oilseed rape or cherry with willow SRC. Silvopastoral agroforestry reduce heat stress for livestock,enhance their well-being and productivity, and provide fodder. Hedgerows, shelterbelts and riparian buffer strips are the most visible and recognisable forms of agroforestry in the UK. Only 3% of the UK farmed area practises agroforestry.

The establishment of agroforestry systems requires careful planning and well-designed layouts. Depending on the tree type, the agricultural components and their spatial and temporal arrangement, competition for light, nutrients, and water, can intensify, potentially leading to yield reduction. However, with appropriate planning and precise spatial arrangements, the advantages of agroforestry can surpass those of monocropping systems.

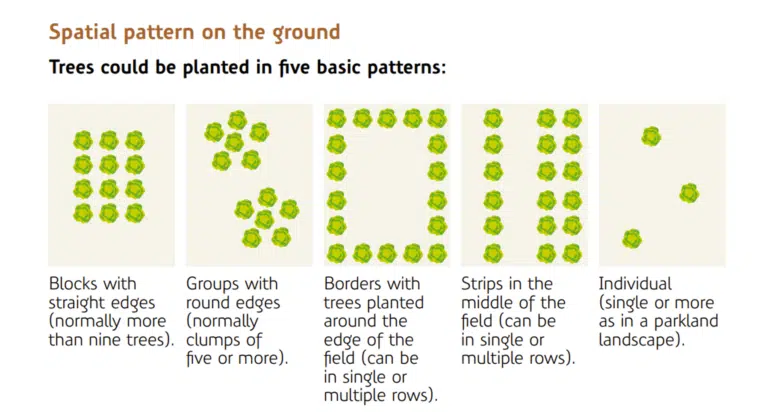

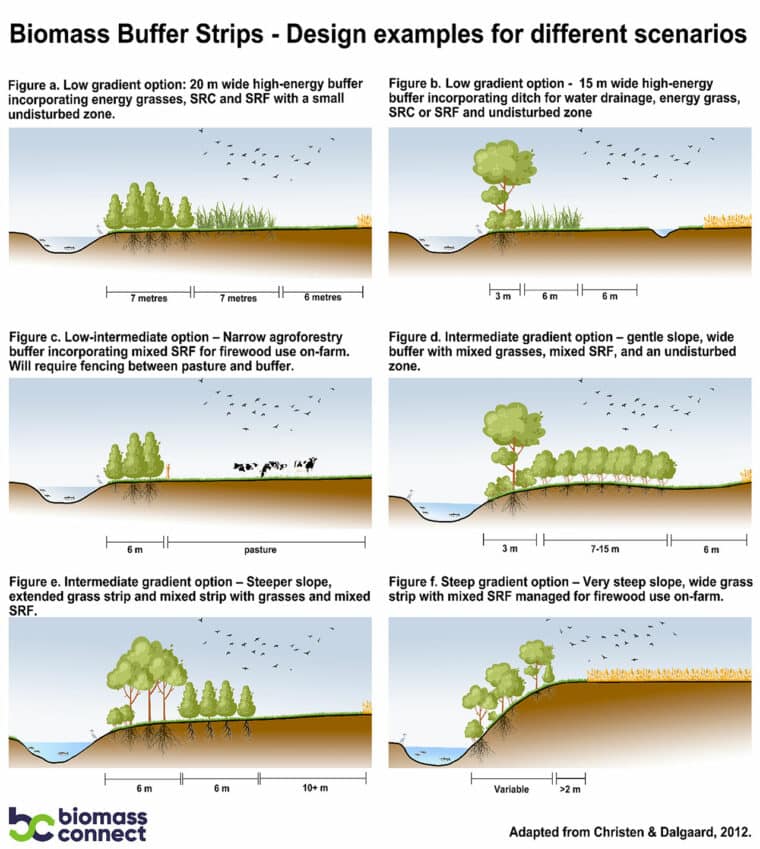

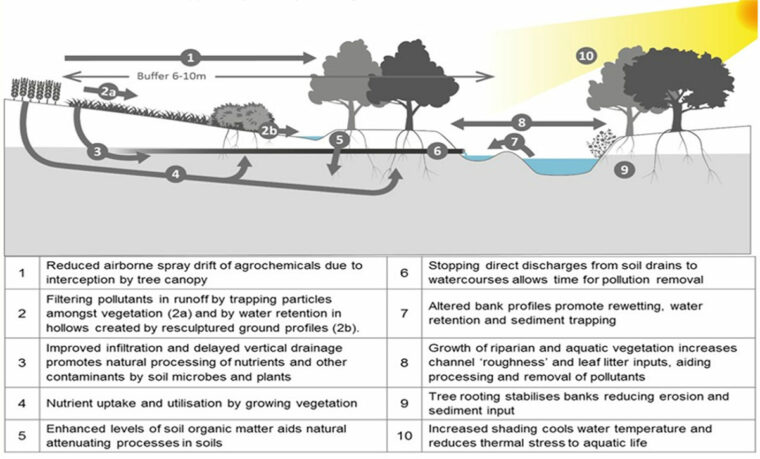

The format by which agroforestry is implemented can vary widely, from uniform rows of arable crops and forestry, to expanding the width and amounts of hedgerows on pastureland. The agroforestry handbookprovides practical guidelines and design considerations (Fig.1) for establishing agroforestry systems.

Why integrate biomass crops into agroforestry systems?

Strategic planting of dedicated biomass tree crops in agroforestry systems can increase landscape heterogeneity and enhance ecosystem function. There are several benefits of incorporating biomass crops into agroforestry systems:

Carbon Sequestration and tackling climate change

Incorporating trees or shrubs into farmlands or pastures has proven to be a highly effective strategy for enhancing carbon sequestration compared to monoculture fields of crops or pastures. The integration of biomass crops within agroforestry systems serves as an effective mechanism for capturing and storing carbon from the atmosphere through the process of photosynthesis. These biomass crops play a substantial role in reducing atmospheric carbon dioxide concentrations by accumulating relatively large quantities of carbon in above and below-ground biomass and in the soil. These crops exhibit the potential to sequester significant volumes of carbon dioxide that they absorb during their growth, storing this carbon within the soil. Additionally, the fallen leaves and branches from these biomass crops contribute organic matter to the soil, further enhancing long-term carbon storage.

The root structure of biomass crops continuously expands throughout their life cycle, storing and transferring carbon to the soil. For instance, a study conducted in Southern England illustrated that SRC willow plantations had reduced soil respiration (912 ± 42 g C m-2 yr-1 ) and acted as a net carbon sink of 221 ± 66 g C m-2 yr-1). Another study showed that when biomass crops are established in areas with low carbon content (less than 60–70 Mg C/ha at 0–30 cm depth), they have the potential to increase soil carbon stocks. Additionally, planting biomass crops in degraded land can sequester carbon ranging from 0.6 to 3.0 Mg C ha-1 yr-1. The considerable benefits of biomass crops in sequestering carbon not only underscore their significance in mitigating climate change and reducing greenhouse gas emissions but also position them as vital crops for long-term carbon storage. The carbon stored has potential to then be sold in carbon credit markets.

Biodiversity enrichment

Biomass crops are beneficial for biodiversity compared with conventional cultivated areas of arable food crops. Several factors contribute to their positive impact, including longer rotation periods, low fertiliser and pesticide requirements, enhanced soil protection, greater spatial diversity, reduced disturbances during the growth phase, and the option to conduct harvesting during the winter or after the bird breeding season, minimising disruptions. Integrating biomass crops into agroforestry systems creates a diverse range of habitats and resources that attract various wildlife species. This combination of factors establishes an environment conducive to the survival and proliferation of diverse plant and animal species.

Biomass crops, such as willow and poplar, establish dense and varied stands that offer various niches and microhabitats. For instance, SRC willow contributes significantly to plant diversity when integrated into existing landscapes and agricultural systems. SRC willow plantations exhibit higher plant species richnessand increased weed cover compared to neighbouring arable agricultural lands. For example, a studyfound 27% greater plant species richness (133 flora species) and greater weed cover on SRC willow plantation when compared to the neighbouring arable agricultural land. Furthermore, a study into silvopastoral agroforestry, with 35-year-old poplar stands within grazed permanent pastures, found this interaction to offer a viable way of increasing the diversity of invertebrates, arthropods, and birds in grassland systems. The increased biodiversity within agroforestry systems with biomass crops contributes significantly to natural pest control. These ecosystems attract beneficial insects, such as ladybugs and parasitoid wasps, helping regulate pest populations. Consequently, this can reduce the need for chemical pesticides and promote more ecologically sustainable pest management practices.

Biomass crops, especially when integrated into agroforestry systems, provide valuable opportunities for fostering and preserving biodiversity, with positive effects often observed at the field scale. However, it is important to note that the impact on biodiversity within biomass plantations can vary significantly based on factors like plantation management, age, size, and heterogeneity.

Water and air quality improvement

Agroforestry systems with biomass crops can help regulate water flow, reducing surface runoff and the associated risks of flooding and water pollution. Biomass agroforestry systems, such as riparian buffersare recommended as a solution to combat nonpoint source pollution from agricultural land.

In areas where agricultural land is more intensively managed, nitrate and phosphorous leaching and run-off are identified as the main source of pollution resulting in eutrophication of lakes and waterways. Biomass crops can act as biological filters that take up and utilise nutrients before they enter watercourses. The crops have deep root systems that serve as safety nets, absorbing nutrients that have leached below the rooting zones of most arable crops.

For instance, a study showed increased nutrient removal (between 30-99% of nitrate and 20-100% of phosphorous) when biomass trees were incorporated into agricultural fields. Biomass crops such as willow SRC have been shown to be particularly effective for shown to be particularly effective for permanent nutrient removal of 55 kg PO43−eq ha-1 yr-1 based on field trials conducted in Northern Ireland.

Also, biomass crops (depending on their height and location within the landscape) can act as windbreaks and shelterbelts as well as protecting buildings and roads from snow drifts, and noise pollution. A mixture of both SRC and SRF in agroforestry system can offer the benefit of improving air and water quality.

Reduce soil erosion and improve soil health

The integration of biomass crops into agroforestry systems provides significant benefits for soil health and erosion control. Biomass crops have extensive root systems that help bind soil particles and prevent them from being washed away during heavy rainfall or strong winds. Biomass crop root systems reduce erosionby enhancing water infiltration, minimizing impacts by water droplets, intercepting rain and snow and stabilizing soil through their roots and leaf litter. Biomass crops have the potential to improve the soil’s physical, chemical, and biological properties by adding substantial amounts of above and below-ground organic matter, as well as the release and recycling of nutrients when integrated into agroforestry systems.

For instance, black locust roots form a symbiotic association with nitrogen-fixing bacteria, which form nodules on the roots and convert atmospheric nitrogen into ammonium in the soil, thereby enhancing soil fertility. When these crops are planted on marginal lands, they have the potential to rehabilitate and improve soil conditions. Black locust has been used successfully in mine reclamation in Germany and in reclaiming degraded lands in Romania. Studies have shown willow and poplar tree potential for use in the phytoremediation of soil contaminated with heavy metals.

Current UK policy

Biomass crops and SRF (<8-year rotation) are ineligible under current rules for woodland grants and incentives. There is therefore a need to develop policies that facilitate the integration of these crops into farming systems, acknowledging the environmental benefits provided by these crops, including improving soil health, carbon sequestration, enhancing biodiversity, and improving water and air quality. To encourage planting of these biomass crops on farms, grant options may be included in support schemes that farmers are already familiar with, such as the Environmental Land Management (ELM) Scheme in England, AgriEnvironment Climate Scheme (AECS) in Scotland, Sustainable Farming Scheme (SFS) in Wales, Small Woodland Grant scheme or the Forest Expansion Scheme in Northern Ireland, and the woodland grants and incentives available for establishing and maintaining woodland for nature recovery.

Further information:

Related Biomass Connect Articles:

- How does Short Rotation Coppice (SRC) willow affect biodiversity?

- What effect does planting biomass crops have on soil carbon?

- Biomass Buffer Strips – using biomass crops in multipurpose land management

Other resources:

- The Agroforestry Handbook

- Forestry Commission – Grant funding for woodland

- Funding for landowners – Nature based solutions to reduce flood risk

- Natural Flood Management Handbook – A practical guide for farmers.

Latest Technical Articles

Production of Switchgrass (Panicum virgatum) as a biomass feedstock

Key messages:

Switchgrass is a tall-growing, warm-season, perennial C4 grass native to North America. It grows in small dense clumps and is capable of producing high biomass yields with low inputs, grows well on marginal land, and tolerates a wide range of conditions.

Switchgrass is established from seed and has relatively low establishment costs compared to perennial biomass crops.

It takes approximately 2-4 years to mature and can remain productive for 15-20 years depending on crop management, soil type, climate and variety. Average yields of 7.57 to 12.72 dry tonnes per ha is achievable in the UK depending on management and harvest time.

Successful establishment requires attention to seed dormancy and weed control as well as proper depth and time of planting.

Switchgrass has several uses and benefits including control of soil erosion, forage for livestock, wildlife habitat and feedstock for biofuels.

Introduction

Switchgrass (Panicum virgatum) is a tall-growing perennial, warm-season (C4) grass native to North America. It grows in small dense clumps and is capable of producing high biomass yields with low inputs, and grows well on marginal or contaminated land and tolerates a wide range of conditions. Switchgrass consists of two ecotypes, the upland and lowland ecotypes. The upland ecotype has short fine stems and is more tolerant to drought and cold environments. The lowland ecotypes have thicker and taller stems and grow in wet areas with mild winter temperatures. They have late flowering and are adapted to warmer climates, but have lower drought and cold resistance than upland ecotypes. The lowland ecotypes are higher yielding compared to the upland varieties. The upland ecotypes however mature early compared to the lowland varieties.

Switchgrass grows to a height of 50 – 270cm. It takes approximately 2 – 4 years to mature and can remain productive for 15 – 20 years depending on crop management, soil type, climate and variety.

Uses and Benefits

- Switchgrass is a valuable soil protection cover. It is useful in soil erosion control and used in streamside buffers. It has a dense canopy and extensive network of roots which reduces raindrop impact, water runoff, and soil erosion.

- It is a good forage cover and habitat for a variety of wildlife. The canopy structure of switchgrass provides habitat for some birds, reptiles, amphibians, and mammals.

- The plant is an excellent forage for cattle and can be used as livestock bedding.

- It is used as an ornamental plant in gardens and landscaping.

- Switchgrass is a suitable feedstock for biodegradable plastics and for production of ethanol and butanol.

- Switchgrass has carbon sequestration potential and could reduce atmospheric Greenhouse Gas Emissions.

Establishment

Land management before planting in existing landscapes is important to scout for and control perennial weeds within the field to minimize stand failures in the establishment phase. Weeds, if not effectively controlled during the establishment phase, can result in crop failure. Switchgrass is planted by seed at a recommended depth of 0.5 – 2cm and at seeding rates of 200-400 pure live seeds (PLS) m-2. A seeding density of 5 – 15kg/ha is recommended depending on the variety and soil conditions. Switchgrass requires a firm smooth seedbed and can be planted by both no-till and conventional tillage. Conventional seed drilling provides more uniform stand development and seed depth.

Switchgrass displays a high level of dormancy which presents a challenge for germination. Breaking seed dormancy is important to reduce the risk of establishment failure and the costs associated with reseeding. Studies have reported various methods to break the seed dormancy of switchgrass including chemical, mechanical, thermal, and hormonal seed treatment. The seed dormancy of switchgrass is affected by the length of seed storage, storage conditions, quantity of seeds and soil conditions. It is recommended to conduct germination tests and treat seed dormancy by stratification (i.e., soaking seeds in water for about 1 month at 5-10oC then re-drying or by after-ripening (i.e., holding seeds at moderate or preferably at elevated temperatures until the dormancy is broken).

The ideal time to plant switchgrass is early spring after the last frosts (May to mid-June) when soils are moist, and the root system has plenty of time to establish. Switchgrass is a warm-season grass and requires a soil temperature above 10oC for satisfactory germination.

Rolling is recommended both before and after sowing to conserve the moisture in the seedbed followed by the application of broadleaf herbicide to control weeds. Weed competition is a major reason for switchgrass stand failure, especially during establishment. It is important to control weeds to avoid competition. Soil testing is recommended before planting to determine recommended fertiliser application rates to apply. Depending on the soil, nitrogen fertiliser application may not be necessary during the planting year as this will encourage weed growth and increase the risk of switchgrass being outcompeted by weeds as well as increase the establishment cost.

Site Suitability

Switchgrass establishes best on well drained, fertile loam or sandy loam soils, but it can establish and persist under highly variable soil conditions. Switchgrass can be grown on marginal land not suitable for food and feed production and it will tolerate short periods of waterlogging and, depending on the variety, has good tolerance of heat and drought stress. A study investigated different varieties of switchgrass for adaptation in Europe and found that the main factors determining the adaptation of varieties is latitude of the origin of the variety.

Biomass production and harvesting

Average yields of 7.57 to 12.72 dry tonnes (t) per ha are achievable in the UK depending on management and harvest time. A study in the UK of a 2-4 year trial across four sites found lowland varieties (NL93/2) to have a yield potential of 9.63 t ha-1 yr-1, and upland varieties (Shelter and Cave-in-rock) to have yields of 7 t ha-1 yr-1. Switchgrass compared to other C4 grasses like Miscanthus (Miscanthus x giganteus), has a relatively lower yield. Miscanthus average yields of 22 t ha−1 yr−1 have been observed in Europe and the US compared to 10 t ha−1 yr−1 of Switchgrass. In areas with sufficient rainfall, sustainable yields of ∼15 Mg ha−1 yr−1 may be achievable by applying ∼50 kg N ha−1 yr−1. In South England, the dry matter yield of switchgrass (Cave in Rock variety) grown on low productive arable crop land increased by 43% by the application of 100 kg ha-1 Nitrogen fertilizer.

Mature switchgrass can be harvested once or twice per year with conventional haying equipment and usually commences from the second year after sowing. Harvesting can be conducted after frost when plants have senesced and translocated nitrogen and potassium back into the root system. Harvesting once per year will remove fewer nutrients from the soil, maximize biomass recovery and maintain stands. Harvesting twice per year will require more nitrogen application to compensate for the nitrogen removed in the first harvest. Harvesting more than twice a year adversely affects long-term productivity and persistence of the crop. Switchgrass traits can be significantly affected by the harvest timing.

Switchgrass is suitable for thermochemical processes such as combustion, gasification, and pyrolysis. A study found switchgrass composition of lignin (12.3), cellulose (46.1), hemicellulose (32.2), ash (4.7) to be suitable for thermochemical processes, hence it is an attractive feedstock for bio-based products.

Feedstock | Cellulose | Hemicellulose | Lignin | Ash |

Miscanthus | 41.9 | 26.6 | 13.3 | 3.2 |

Switchgrass | 46.1 | 32.2 | 12.3 | 4.7 |

Wheat straw | 34.9 | 22.5 | 21.3 | 9.4 |

Rice straw | 41.6 | 31.5 | 12.5 | 14.4 |

Corn stover | 39.4 | 33.1 | 14.9 |

|

Sorghum | 15.0 | 12.3 | 5.8 | 0.4 |

Sugar cane | 48.6 | 31.1 | 19.1 | 1.2 |

Hardwood (beech) | 43.3 | 31.8 | 24.4 | 0.5 |

Softwood | 40.4 | 31.1 | 28.0 | 0.5 |

Source: Adapted from Pauly and Keegstra (2008)

Pests and Diseases

Switchgrass disease levels are relatively low and not considered a cause for concern. Fungal diseases such as rust, leaf spot and smut have been reported to affect switchgrass. Varieties developed in dry areas will be more susceptible to fungal disease when grown in humid conditions. The lowland ecotypes are known to be more resistant to rust. Aphid, leaf miners, double-lobed moths and fruit flies occasionally attack switchgrass causing a reduction in yield. Damage from rabbits and slugs can occur during the first year of establishment.

Economics

Switchgrass has a relatively low establishment cost compared to other perennial grasses like miscanthus, and other biomass crops like willow and poplar. Switchgrass is cultivated by seed and has low input cost (around £357/ha), thus the establishment is of low cost. Where production costs have been considered, research indicates that production cost of switchgrass in some European countries including UK indicated values from 130 to 250 £/ha/year. This makes it a practical option among biomass crops. There is little data available on the commercial production of switchgrass in the UK. Most existing plantings are for research purposes.

Latest Technical Articles

Reed Canary Grass as a Biomass Crop

Key messages:

- Reed canary grass is a perennial, lignocellulosic crop that is native to the UK and has multiple uses.

- It is established from seed, making set-up costs lower than for many other perennial biomass crops.

- Reed canary grass is a shorter-term crop (5-10 years) than Miscanthus and willow, with average yields of 5-7 tonnes of dry matter per ha, depending on management.

- It is tolerant of a range of land types and conditions including flooding, drought, and freezing.

- Reed canary grass can be grazed in early summer (depending on the variety) and harvested for diverse other uses from late summer until early spring. This extends the annual window of biomass availability and supports multiple end uses (e.g. anaerobic digestion, combustion, animal bedding, seed supply, game cover).

Introduction

Reed canary grass (Phalaris arundinacea L.) is a multipurpose, lignocellulosic perennial crop native to Europe, Asia, and North America. It can be grown on poorly productive land and tolerates a wide range of conditions. Reed canary grass is found in diverse habitats including wetlands and riparian zones but also drier areas like roadsides, forest margins, pastures, and disturbed areas. It is a fast-growing crop reaching heights of 1.5-2 m in a growing season, and, depending on management, can remain productive for 5-10 years.

Uses and Benefits

Reed canary grass can be utilised in diverse energy conversion processes like combustion, gasification, pyrolysis, and anaerobic digestion.

Reed canary grass can be utilised in diverse energy conversion processes like combustion, gasification, pyrolysis, and anaerobic digestion.- Reed canary grasshas a high gross calorific value (dry ~18.2 MJ kg-1), exceeding that of wheat and Miscanthus. Ash content (~3-8 %) depends particularly on harvest, management, and site.

- Reed canary grass has carbon sequestration potential and can be used for a prolonged ‘fallow’ period in a rotation where soil health can recover from more intensive arable practices and organic matter can be accrued.

- Reed canary grass creates habitat for diverse wildlife including birds and small mammals.

- Reed canary grass can mitigate greenhouse gas emissions and reduce nitrate leaching, acting as a buffer crop.

- Reed canary grass can be integrated into multifunctional landscapes as a biomass crop providing benefits of supporting ecosystem services and mitigating environmental impacts.

- Reed canary grass can be used for livestock feeding provided it is low in alkaloids (eg. Marathon or Palaton variety). It has good absorption properties and is a viable alternative to straw as bedding material for livestock.

- Reed canary grass has potential to remove contaminants from soil and water.

Establishment

Reed canary grass is planted by seed. It requires a firm, smooth seedbed and timely weed control during establishment, with fertiliser where nitrogen is limiting. Seed can be broadcasted or planted using a conventional seed drill. Conventional seed drilling provides more uniform stand development and seed depth. The ideal time to plant Reed canary grass is between March and April when soils are moist, and the root system has plenty of time to establish. The recommended seeding rate for forage production is 5-10 kg ha-1 with row spacing of 12.5 cm, at a depth of about 2 cm. Rolling is recommended both before and after sowing to conserve the moisture in the seedbed followed by application of broadleaf herbicide to control weeds. Growth can be slow during the first year of cultivation while the root and rhizome system establishes. Harvesting can usually commence from year two. Nutrients translocate to the rhizomes over the autumn and winter period, providing energy for new shoots in spring, and improving the sustainability of the crop and quality of the biomass for combustion purposes.

Site Suitability

Reed canary grass is highly tolerant to waterlogging (established stands can tolerate extended periods of inundation) and a wide pH range from pH 4.9 to pH 8.2. It can thrive on marginal land unsuitable for food or feed production. Once established, Reed canary grass is one of the most productive temperate grasses during drought due to its deep rhizome and root system. As a temperate grass used extensively in Scandinavia, it is also highly tolerant of freezing conditions.

Biomass production and harvesting

Average yields of 5-7 tonnes per hectare are achievable in the UK, depending on management, although ‘pushing’ the crop may decrease crop overall persistence. Yields will be improved by fertilisation where nutrients are limiting although over fertilising may promote lodging. Harvesting the crop green will reduce sustainability, as nutrients not yet translocated to the below-ground biomass will be removed.

Reed canary grass under two harvesting regimes (autumn, LHS; spring RHS) on shallow, stony soil in West Wales.

Harvesting can be conducted with conventional grass harvesting machinery and usually commences from the second year after sowing.

The timing of harvest depends on the intended market/end-use. Forage quality is best in spring and early summer, while harvest for anaerobic digestion can extend from summer until autumn senescence begins. For combustion and animal bedding, harvesting is best delayed until late winter or early spring, where combustion quality will be improved through nutrient translocation below ground, leading to lower contents of sodium, potassium, chlorine and moisture (ca. 10-15%). Spring-harvested biomass requires little or no drying. The crop is typically mown first before being baled and transported.

Alternatively, the grass can be cut and chipped using a forage harvester. Eliminating the crop after productive years will be easiest using herbicides e.g., glyphosate, although repeated cutting and conventional tillage may suffice.Although harvesting reed canary grass green will remove nutrients, increasing the need for fertiliser, research has shown costs can be reduced using sewage sludge or nitrogen-fixing legumes.

Pests and Diseases

Reed canary grass disease levels are relatively low and are not considered a cause for concern (they include brown rust, mildew, buff spot, powdery mildew, and Rhynchosporium (leaf scald)). However, reed canary grass can be attacked by insect larvae, which feed inside stem bases and can occasionally significantly reduce yield. Damage from rabbits and slugs can occur during the first year of establishment.

Economics

Returns during the first year are low, as establishment costs will not be balanced by revenue from biomass production. A study conducted in the UK found an average gross margin of £153.89 ha-1 for reed canary grass grown in multiple sites. The gross margins ranged from a minimum of £110.60 ha-1 to a maximum of £219.40 ha-1 across the sites studied. The differences in the gross margin were attributed to the variations in yield among different sites and prices of the biomass.

Latest Technical Articles

Does production of biofuel mean less food production?

Take home messages:

- The food versus fuel debate calls into question the ethics of diverting land from food to biofuel production.

- Bioenergy production from first generation (edible) biofuel feedstock may compete with food production and as consequence affect food security.

- A shift towards increasing production of second generation (non-edible) biofuel feedstocks and third generation biofuels along with advanced technologies of genetically engineered algae biomass would avoid the competition for food.

- Food and bioenergy need not compete for land. Biofuel crops should be integrated into existing landscape and agricultural lands in a multifunctional approach to improve use as food, fuel and for other ecosystem services.

Introduction

Biofuels have the potential to reduce reliance on fossil fuels whiles reducing environmental impacts and greenhouse gas emissions. Biofuel makes a small contribution to our energy demand whiles fossil fuels contributing approximately 87 percent of energy having a negative impact of increase in global warming. To limit global warming, biofuel production should be increased from 9.7 × 106 GJ d−1 to 4.6 × 107 GJ d−1 between 2016 and 2040. This would require large scale deployment of biofuel feedstock production and advanced technologies in biofuel production. However, there are trade-offs related to the expansion of bioenergy feedstock production by diverting land use from food to biofuel production, which poses a threat to food security especially in developing countries, and directly or indirectly leading to deforestation and other changes of land use that have a negative effect on greenhouse gas emissions. This calls into question the ethics of diverting land from food to energy and whether it implies less food production. In this article, we provide a review of the food versus fuel debate, whether a shift to other alternative biofuel feedstocks would avoid this competition for food.

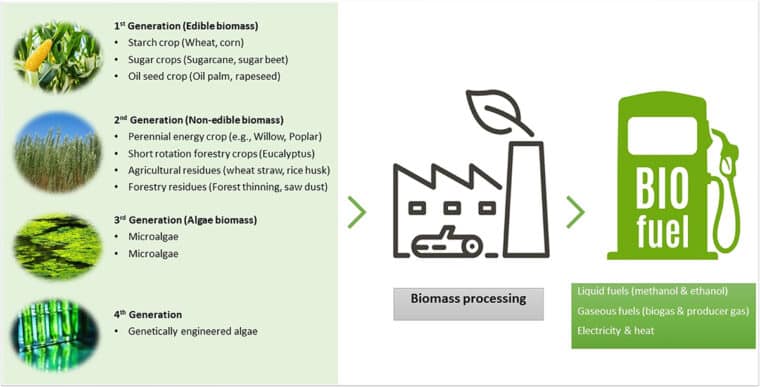

Food versus fuel debate

The food versus fuel debate calls into question the ethics of diverting land from food to energy production. The opinion piece written by the Guardian columnist, George Monbiot in 2004, brought attention to the issue of devoting land to fuel production in his article entitled ‘Feeding cars, not people’. He argued that the expansion of biofuel production is at the expense of food which is much needed to feed a growing population especially the food insecure in developing countries. A wide range of perspectives on the debate of food versus fuel further emerged following increases in world crop prices for cereals and vegetable oils which are raw materials for producing biofuels. Biofuels are produced from the fermentation of biological feedstocks containing fermentable sugars, lipids, or carbohydrates. Biofuels are categorized into first, second, third and fourth generation biomass feedstocks (see figure 1).

What are the implications of use of first generation feedstocks for biofuels?

First generation biofuel feedstocks have been at the centre of the food versus fuel debate. First generation biofuels are produced from easily accessible and edible fractions of food crops. They produce large amounts of lipids or carbohydrates that are easily converted into biofuels. Bioethanol is produced from sugar crops (e.g., sugarcane, sugar beet and sweet sorghum) and starch crops (e.g., wheat, maize, and cassava), while oil seed crops such as rapeseed, sunflower, oil palm, and soybean may be used for production of biodiesel. These edible feedstocks have been mainly used for producing biofuels globally and have been highly commercialised, contributing over 50 billion litres of the total fuels produced per year. However, there are trade-offs with producing such edible feedstocks for biofuel production.

First, increasing production of first generation biofuel feedstock impacts food security, due to competition for direct land use. Thus, any dedicated use of productive land for production of biofuel feedstock inherently comes at a cost of not using the land for food or feed production. This claim is however based on the assumption that land is a limiting factor for global food production and to meet the rising demand for food and fuel will require newly cleared land leading to deforestation and increases in greenhouse gas (GHG) emissions. On the other hand, others have argued that global land is not a limiting factor when land cover, land use, and productive potential are considered.

Another facet to the debate is that the demand for biofuels has an impact on food prices, which disproportionately affect poor people in the global south who spend roughly half of their household incomes on food. The increased demand for production of biofuels from food grains and oilseeds in the U.S. and the EU contributed to this increase in food price, much of which was due to policies that incentivised production of biofuels. On the other hand, some studies have shown that biofuel prices do not seem to affect food commodity prices and have not been the most important contributing factor for food price inflation and that, different biofuels have different impacts on prices of food commodities. Such studies have found no strong evidence that biofuels such as ethanol would drive food commodity price.

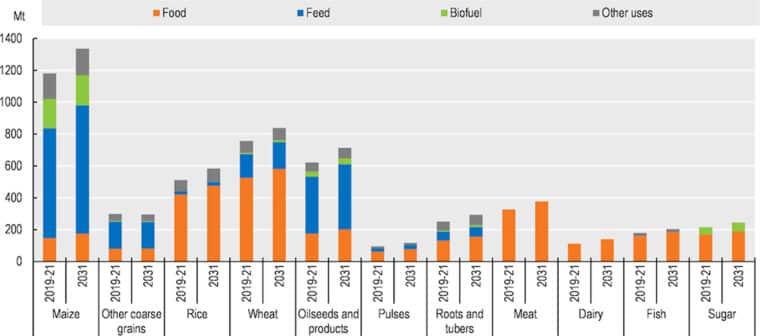

Furthermore, there is evidence that these biomass feedstocks may not have a direct impact on food production since they are grown for different purposes. For instance, from the data on global use of major food commodities (see figure 2), the volume of use of maize, a major biofuel feedstock is mostly used for animal feed. The OECD-FAO projections on global use of maize is largely more towards animal feed production. Thus, the type of biomass production may not have a direct impact on food production since they are grown and used for different purposes. Hence, there is the need to examine the interdependencies between the multiple end-uses of biofuel feedstocks.

Figure 2: Global use of major commodities

Lastly, the studies have shown that first generation biofuels are poor crops for biodiversity and compete for water resources. For example, production of maize presents the risk of soil erosion, soil damage and runoff water which affects soil health. Limits should be set on bioenergy support schemes to regulate or control the amount of food and feed crops that can be used for production of biofuels.

Would second generation biomass crops avoid the competition for food?

In view of the negative trade-offs of first generation biofuel crops, second generation biofuel feedstocks which are derived from non-edible biomass have been proposed as more suitable for production of biofuels, as these feedstocks do not compete with food production. Second generation biofuels are based on lignocellulosic feedstocks including perennial energy crops (e.g., Miscanthus, short rotation coppice willow, poplar), Short rotation forestry (e.g., eucalyptus, black locust, paulownia), agricultural residues (e.g., forest thinning, sawdust, sugarcane bagasse, rice husk, rice bran, corn stover, wheat straw, and wheat bran), and forestry residues (e.g., small branches and bark from forest thinning operations, conservation management operations, wood pellets, or wastes from wood processing industries such as sawdust).

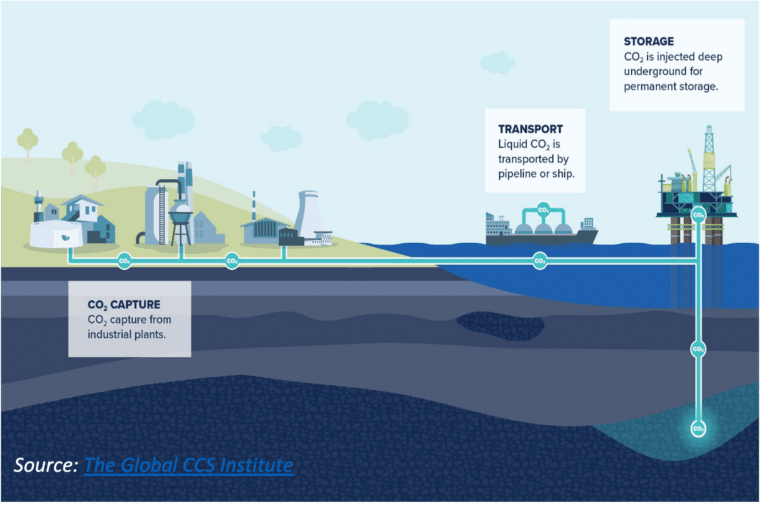

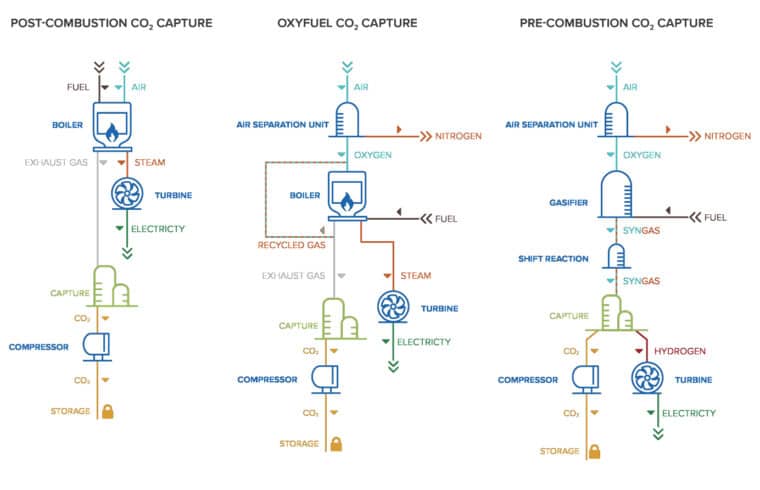

Compared to first generation biofuel feedstock, these non-edible feedstocks do not compete for food, can grow on marginal land, do not require much input such as fertilizers, and provide additional ecosystem benefits such as increasing biodiversity and soil carbon and reducing greenhouse gas emissions. They produce high amounts of biomass and can be harvested regularly over a long period and be processed for use as biofuels. These biomass crops have a potential to play a key role in decarbonisation of economies, both as a substitute to fossil fuel energy reducing greenhouse gas emissions, as well as to generate negative emissions using carbon capture and storage (BECCS).

However, the competition for land and food may still persist if productive land for food production is used for growing second generation biomass feedstocks. Planting second generation biomass feedstocks on marginal land avoids the competition for land use and food. Also, bioenergy crops should be integrated into existing landscape and agricultural land in a multifunctional approach to offer multiple benefits including use as fuel and other ecosystem services.

Shifting to third generation bioenergy feedstock and more advanced technologies?

Third and fourth generation biofuels are more promising as they do not create such land use and food competition. Third generation biofuels are non-food marine biomass derived from algae including, seaweeds (green, red, and brown macroalgal species) and microalgae. These algae biomass have higher growth rates and do not require an arable or big land area for production and hence do not compete with land for food and also act as carbon sink.

With advanced technologies of genetic modification of microalgae, fourth generation biofuels are seen as more promising sustainable biofuel feedstock due to their high biofuel productivity and ability to capture large amounts of carbon dioxide. Research is still advancing in the use of genetically modified algae. As these technologies become more advanced, efficient, and economical, they could replace uses of first generation biofuels and fossil fuels for sustainable energy production.

Sustainable biofuel production in the UK

In the UK, bioenergy plays an important role in decarbonising the energy system by reducing greenhouse gas (GHG) emissions, expanding renewable energy and moving towards a low-carbon economy. Domestic biofuel crop production however constitutes a small component of existing agricultural land. Less than 1.4 percent of 18.6 million ha of agricultural land in the UK is currently used for bioenergy crops. In 2020, 121,000 ha of agricultural land were used to grow bioenergy crops. Of this, 92 percent constituted edible food crops for biofuels (diesel and bioethanol) and biogas, and about 8 percent constituted non-food biofuels used for electricity and heat generation. Future projections to reach net zero ambitions estimates planting about 30,000 ha yearly through to 2035 and estimated cultivation of 70,000 ha of bioenergy crops by 2050. This will certainly require large scale expansion of land for biofuel feedstock production.

A shift towards increasing production of second generation (non-edible) biofuel feedstocks and third generation biofuels along with advanced technologies of genetically engineered algae biomass would avoid the competition for food. The second generation biofuel crops may not necessarily compete directly with food production if grown on marginal lands including under-used, inaccessible, inconvenient, land prone to flooding, or degraded land. It is estimated that 1.4 million hectares of marginal land in the UK could potentially be planted with perennial energy crops by 2050 avoiding competition for arable land for food production. Planting should also be prioritised on low quality agricultural lands (Grade 5‐4‐3b), public access land, contaminated land and land identified by the Forestry Commission as low risk for woodland creation. However, planting should be avoided on UK Biodiversity Action Plan (BAP) priority habitats, land with cultural value, peatlands and other high carbon soils >120 t C ha‐1.

Food and bioenergy need not compete for land and, instead, should be integrated to improve resource management. Bioenergy crops should be incorporated into existing landscape and agricultural land in a multifunctional approach to deliver multiple outputs from the land including food, biodiversity, climate change, waste absorption, and other societal purposes.

Conclusion

The dilemma of diverting land from food to energy production has made bioenergy crops controversial with wide range of perspectives. Biofuels produced from using edible biomass stocks have been at the centre of the food versus fuel debate, with serious criticism that it may lead to competition with food, increase food prices, deforestation and other changes of land use that have a negative effect on greenhouse gas emissions. A shift towards increasing production of second generation (non-edible) biofuel feedstocks and third generation biofuels along with advanced technologies of genetically engineered algae biomass would avoid the competition for food. Planting second generation biomass feedstocks on marginal land avoids the competition for food production. Food and bioenergy need not compete for land, instead, biofuel crops should be integrated into existing landscape and agricultural lands in a multifunctional approach to offer multiple benefits including use as fuel and for other ecosystem services.

Latest Technical Articles

Hemp as a Biomass Crop

Take home messages:

- Industrial hemp has greater versatility and profitability than many other biomass crops like giant miscanthus, willow, poplar and switch grass.

- It yields high biomass (12- 15 t/ha of air-dried biomass) with minimum input of water, fertilizers and pesticides.

- The best applications for industrial hemp include co-production of hemp products like insulation material for buildings, hemp paper, textiles etc with biofuels.

- It is an excellent rotation crop that fits well with food and feed crops and improves the yield of the subsequent crops due to the beneficial effects of hemp on the soil like improving soil structure and reducing parasitic nematodes and fungi.

- The UK lags behind its European counterparts in hemp production due to the regulatory forces and unless changes to these regulations are made, farmers may be less attracted to the produce hemp.

Introduction

The conversion of biomass to biofuels has gained heightened interest due to the increasing demand for sustainable and eco-friendly sources of energy. Traditionally, biofuels have been produced from starchy or sugar crops such as corn, wheat, sugar beets and sugar cane. However, this gives rise to competition between food versus energy. Therefore, there is a need for dedicated non-food energy crops, especially those where the whole plant biomass can be used for energy production resulting in potentially higher land use efficiency. Moreover, if such crops could be fitted into a crop rotation system with food and feed crops land use efficiency can be further increased. Energy crops are projected to play a significant role in the future of bioenergy due to the paucity of biomass from forestry output and the scarcity of acceptable “waste” streams.

Industrial hemp (Cannabis sativa L.) is one of the oldest crops in the world traditionally grown for its fibre. Hemp fibre was the main fibre for maritime ropes and sails and was used extensively as a raw material for cordage and textiles. However, its production declined in the middle of the 19th century due to the disappearance of the sailing navy, competition from natural fibres like cotton and jute and later due to intensive development of synthetic fibres.

In the 1930s cultivation was forbidden in most Western countries and in North America due to its genetic closeness to marijuana which created a lot of confusion and social, political and moral controversies. The 1990s marked renewal of hemp cultivation for agricultural, industrial and scientific reasons throughout the world mainly due to increasing consideration of natural resources, energy conservation and biomass conversion to bioproducts and biofuels.

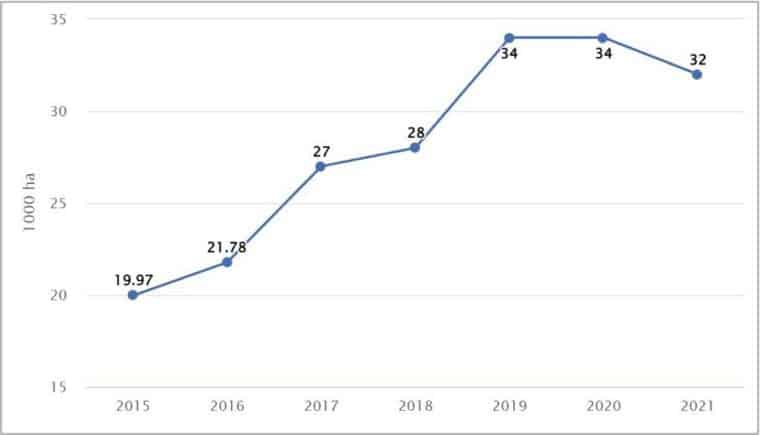

Since 1992, France, the Netherlands, England, Spain and Germany have passed legislation allowing for the commercial cultivation of industrial hemp. Two years later, Canada followed in the footsteps of the EU passing regulations that allowed farming of hemp. The area dedicated to hemp cultivation in the EU (fig 2) has increased significantly from 19,970 hectares (ha) in 2015 to 34,960 ha in 2019 (a 75% increase). In the same period, the production of hemp escalated 62.4% from 94,120 tonnes to 152,820 tonnes. France is the leading producer in Europe, accounting for more than 70% of EU production, followed by the Netherlands (10%) and Austria (4%).

Fig 2. EU land used for hemp Fig 2. EU land used for hemp cultivation from 2015- 2021cultivation from 2015- 2021

Recently there has been renewed interest in hemp as an insulating material as well as a feedstock for specialist paper. It is also an excellent rotational crop. It uses a fraction of the water needed to grow cotton, absorbs more carbon dioxide per hectare than other crops and most trees and its every part is beneficial. Its extensive root system improves soil structure and subsequent crops have less weed pressure. Studies in winter wheat crops grown after hemp have reported yield increases of 10-20%. This may be attributed to decreased parasitic nematodes and pathogenic fungi and reduction in soil water loss and soil erosion due to hemp growth.

Hemp is also highly efficient in ecological reconstruction and land reclamation owing to its phytoremediation capacity i.e its ability to remove heavy metals from the ground. Overtime it can remove heavy metals and other contaminating substances from the deeper layers of the soil as its root system develops. Finally, biochar produced from hemp for soil applications could potentially improve soil carbon sequestration and reduce greenhouse gas emissions.

Important factors in growing hemp for Energy

Soil and Climate

Hemp cultivars adapt well to a temperate climate therefore they can be farmed in most countries in Europe including UK. During the growing season, they require 200–300 mm of rainfall. The amount of rain that falls throughout the summer is less crucial for development than enough soil moisture. A strong tap root system effectively lessens the impact of a brief drought. As a result, seed germination can take up to 8–12 days at a soil temperature of 8–10oC. Young plants may withstand brief frosts of up to -6oC degrees. The duration of the day has a significant impact on how hemp develops. Hence, the recommended time for planting hemp for biomass is at the end of April.

A well-established soil that is nutrient- and organic-rich is necessary for hemp. The soil should have a pH that is neutral or slightly alkaline. A robust root system ensures that plants can absorb water and nutrients from the soil’s deeper layers. In crop rotations with a large proportion of cereals, hemp is a desirable preceding crop because it enhances the aggregative structure of the soil.

Tillage and Cultivar Selection

Hemp requires winter ploughing and spring tillage to prevent soil dryness. The amount of nutrients in the soil and the previous crop should be taken into consideration when deciding how much mineral fertiliser to apply before planting. The amounts of specific fertilisers are as follows: approximately 80 kg/ha of N, 50 kg/ha of P2O5, and 90 kg/ha of K2O. In general, hemp doesn’t need chemical pesticides or weed killers to control weeds, diseases, or pests because it has one of the intensive early growth rates of any agricultural crop. Hemp should be planted at a density of 40–50 kg/ha with a row spacing of 20–30 cm.

There are 75 varieties listed in the EU common catalogue of varieties of agricultural plant species. The main factors that influence the choice of the hemp variety include the suitability for growth in the region and the end product for which it is grown. Most cultivars of hemp are capable of yielding 12–15 t of air-dried mass per hectare genetic and breeding work is carried out to obtain new lines yielding over 20 t/ha of biomass with a high fibre and cellulose content and trace amounts of THC.

What makes hemp a potential bioenergy crop?

The demand for biomass for conversion to energy is rapidly increasing and is expected to accelerate in the coming years. Industrial hemp is valuable due to its high biomass and energy yield per hectare. Several studies have claimed that hemp could be used in energy production as a fuel source with no sulphur emissions either by direct combustion or converted into liquid fuels such as bioethanol. Hemp oil, which was traditionally used as lamp oil, can be used to produce renewable biofuels which emit less carbon monoxide on combustion to replace gasoline for diesel engines thus helping in relieving global warming.

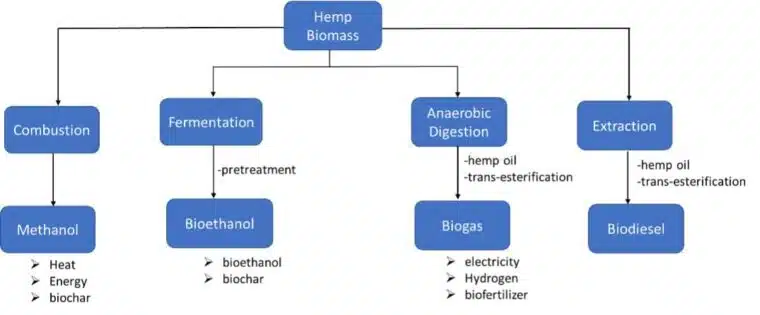

The whole plant can be used to make a variety of products in a biorefinery, including feedstock and biochemicals like succinic acid, heat from briquettes or pellets, electricity from baled biomass and vehicle fuels like biogas from anaerobic digestion or bioethanol from fermentation. In terms of biofuels, hemp can provide, biodiesel made from the pressed seed and bioethanol and methanol from the fermented stalk, all of which are clean renewable alternatives to petroleum-based fuels. The possible pathways for bioenergy production from hemp biomass are illustrated in figure 5.

Hemp is a rapidly growing plant that can withstand high planting density and its total biomass per hectare is similar to other energy crops like the giant miscanthus, poplar, switchgrass and willow. However, the significant advantage of hemp over other energy crops is that the concentration of digestible cellulose and hemicellulose is higher in hemp bast fibres. They contain 73-77% cellulose, 7-9% hemicelluloses, 2-6% lignin compared to 48%, 21-25% and 17-19% respectively in the hurd. On the other hand the cellulose and hemicellulose of hemp hurd are comparable to that in the stems of giant miscanthus, poplar, switch grass and willow (table 1). Notably, 20–30% of the stem biomass in hemp consists of high cellulose fibre, resulting in a higher ratio of digestible sugars to lignin in hemp than in other similar-yielding biofuel crops. These characteristics make hemp an above-average energy crop for some biochemical-based biofuel production and greenhouse gas mitigation applications.

Table 1. Fibre yield and composition of hemp compared to other proposed biomass crops.

| Crop | Biomass (Mg DM/ha/yr) | Cellulose (%) | Hemicellulose (%) | Lignin (%) |

| Hemp fibre | 7 – 34.0 | 73-77 | 7-9 | 2-6 |

| Hemp hurd | 34-48 | 21-25 | 17-19 | |

| Corn stover | 4.6 – 5.5 | 38 | 26 | 17 |

| Switchgrass | 5.4 – 34.6 | 28-37 | 23-27 | 15-18 |

| Giant miscanthus | 10.0 – 44.0 | 50-52 | 25-26 | 12-13 |

| Poplar | 7.7- 17.3 | 42-49 | 16-24 | 21-30 |

| Willow | 6.2-21.5 | 46-56 | 12-14 | 13-14 |

Fuel Quality of Hemp

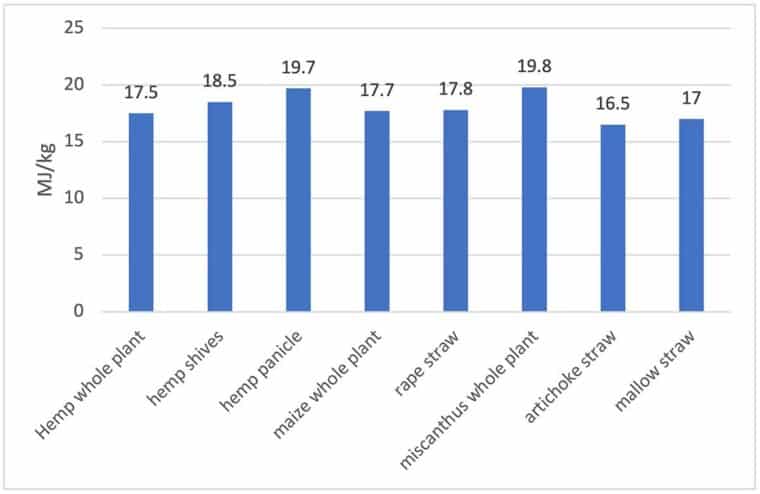

The most important characteristics when evaluating any fuel are the calorific value, ash content, melting behaviour, physical handling characteristics, and any negative effects on heat exchanger corrosion or stack emissions. The following section assess the fuel quality of hemp. Comparison to other fuel crops is made where data is available.

Calorific value

This is the most important property of any fuel. Biomass from both the whole hemp plant as well the by-products (shives and straw) can be a good raw material for energy production. A study at the Teagasc biofuel laboratory reported that, provided hemp can be dried in the field to a moisture of 20%, its net calorific value is higher than many other forms of biomass and much higher compared to that of peat (table 2). Thus, hemp can be an excellent alternative to plants operating on peat fired energy. However, differences in gross caloric value are small.

Table 2. Gross and net caloric values of some biomass fuels.

| Material | Calorific value (MJ/kg) | Assumed moisture content (%) | |

| Gross | Net* | ||

| Hemp | 18.5 | 13.4 | 20 |

| Wood residues | 19.7 | 10.0 | 40 |

| Straw | 18.0 | 13.0 | 20 |

| Peat | 21.5 | 8.9 | 50 |

*heat available with no further drying and no recovery of latent heat

Another study reported the gross calorific values of hemp whole plant and by products compared to other biomass and found them to be comparable or better (fig 6). This study also reported hemp to be resilient to conditions of draught and the energy efficiency per hectare of hemp exposed to water shortage was 10% higher than that of maize under the same conditions confirming the suitability of industrial hemp for energy production.

Ash and Melting Point

The ash content of hemp samples reported in scientific literature varies between 3-4% which is much higher than wood but lower than peat and similar to many non-wood biomass materials. Hemp’s high ash content unavoidably extends boiler maintenance times and causes ash disposal issues but how much longer depends on the application. For instance, it might render the fuel unusable as a pellet feedstock for home heating stoves or boilers in urban areas, be anticipated to have little impact on the rural boiler market and be welcomed by generating stations already using peat with 6-7% ash.

The melting behaviour of ash is also crucial, particularly in applications requiring high combustion temperatures. Low melting temperatures can cause ash to clump together and obstruct grate openings and ash removal systems. The melting behaviour depends on the composition of ash but even with variations the calculated values for hemp ash melting point is higher than most other non-wood biomass. Therefore, under normal combustion conditions ash melting problems should not be an issue with hemp.

Corrosivity and Emissions

One of the major issues with non-wood material is the propensity of the fuel to corrode heat exchanger surfaces and is mainly a function of chlorine, potassium and sodium contents of the material. Hemp has low Cl and Na levels, while its K content is higher than that of wood but similar to that of many straws. Hemp typically has superior qualities to cereal straw, which is effectively burned in power plants in Denmark and the UK, and boilers and Combined Heat Power (CHP) plants in Denmark.

Stack emissions (gases released into the air from boiler stack, chimneys or diesel generator set stack) depend on the plant design, operational factors as well as fuel composition. A fuel with high volatile content and low in sulphur, chlorine, potassium and heavy metals generally tend to have low stack emissions. Hemp stems contain <80% volatile compounds higher than most other plant biomass and moderate levels of S, Cl and K. Although no excessive heavy metals have been measured in hemp, but as hemp as the ability to take up heavy metals from the soil, emissions may be a problem if hemp is grown on contaminated soils.

Profitability analysis

The main factors to consider when determining profitability include crop yields, production costs, energy costs, and the support available for renewable energy. The following section analyses the profitability of hemp grown for energy based on these factors.

Yield

Hemp’s ability to produce significant biomass yields with relatively little water input is one of its main advantages. Hemp requires less water than many other crops, including alfalfa and maize, and may produce 15 t of dry matter with only 250–400 mm of water when grown using modern production techniques. The ambient temperature is another factor that influences hemp development; it can be grown most successfully between the ranges of 13 and 22 °C. As hemp has natural defences against disease and insect attack, growing it requires just a little amount of biocides. These factors make hemp relatively inexpensive to grow.

A 3-year study in Ireland showed that under Irish climatic conditions early sowing has a big impact on yield. Furthermore, seed rate can be chosen to optimize yield and seed cost without any concern about fibre quality. This study also reported that a seeding rate of 30kg/ha gave the highest yields. The study concluded that a harvested yield of 11 t/ha of dry matter, corresponding to about 13.7 t/ha at 20% moisture is achievable and profitable.

Harvesting

The cutting and windrowing procedure is expensive and has a significant impact on field losses, in-field drying, and baling efficiency. There is a need to develop new harvesting machine designs that enable the co-production of improved hemp products, such as high-quality seed and straw which may in turn help to improve the viability of industrial hemp production.

Economics of growing hemp

Hemp grown for energy must be profitable for farmer to produce biomass for energy. In order to ensure encouraging prices for the finished product based on contracts, lower production costs are required. The low-cost production of fibre, seeds, or essential oil for technical uses can slightly increase the profitability of hemp produced for energy. The residual biomass (straw and shives) can subsequently be sold as briquettes for use in the generation of energy.

Hemp production varies greatly on an annual basis, and therefore the profitability of growing hemp inevitably changes as well. In Canada, one of the top hemp producers in the world, the revenue from hemp production is estimated to be $510/acre for fibre, $400/acre for grain, and $580/acre for both fibre and grain hemp production. This is comparable to the suggested returns from a US study.

Another US study which compared hemp with kenaf, switch grass and sorghum found that hemp generated the greatest revenue of these four crops, yielding $2632/ha ($2462/ha from grain and $170/ha from ethanol) compared to $908 for kenaf, 4803/ha for switchgrass and $1725 for sorghum when used for coproduction of ethanol and grain, though hemp had lower biomass yield. These values include the yield and value of hemp and sorghum grain as well as the growing cost for each type of biomass. One study looked at the profitability of hemp by pricing it as an energy commodity with the same price as oil. It found that industrial hemp had a net yearly profit of between €2000 to €3500/ha, which was higher than the earnings from both canola and sugar beetroot. Using organic fertilisers also enhanced profits, though less significantly than for canola and sugar beetroot.

In EU countries, farmers who grow hemp are eligible for area-based direct payments under the Common Agricultural Policy (CAP) provided the hemp variety being cultivated has THC (Tetrahydrocannabinol, the main psychoactive compound in marijuana) content of no more than 0.3% and is listed in the EU common catalogue of varieties of agricultural plant species. In the UK very little hemp farming has taken place in the recent years, in spite of a long hemp farming history, and the nation today falls behind its European rivals significantly. Only 20 farmers in the UK currently cultivate hemp on an area of 800 hectares. The main cause of this is the onerous regulations. Industrial hemp cultivation is legal in the UK with a licence since it is considered a “special purpose” under the Misuse of Drugs Act of 1971 (MDA). As a result, hemp farmers must adhere to strict guidelines for the licensing of controlled substances.

Conclusion

Hemp has great potential to become a promising commodity crop for producing both biofuels and value-added products. It is an excellent rotation crop that fits well with food and feed crops and improves the yield of the subsequent crops due to the beneficial effects of hemp on the soil. The best applications for industrial hemp include co-production of hemp products with biofuels. Its high yield, higher ratio of cellulose to hemicellulose and digestible sugars to lignin and economics of production give it a competitive advantage over other biomass crops like giant miscanthus, willow, poplar and switch grass.

To promote the development of hemp as a biomass crop in the UK, changes to the regulations which require licensing to produce hemp are required. Subsidies for investments in processing facilities and equipment would greatly increase the viability of hemp in existing crop cycles in the grasslands, where hemp biochar can be co-fired with coal to reduce emissions. Hemp producers can benefit from investment in processing equipment that can valorise many potential products from hemp.

Latest Technical Articles

Harvesting of Short Rotation Coppice Willow

Summary

Willow is harvested every three to four years depending on the plant growth and soil conditions. Ideally, harvesting should occur during the dormant season in winter (mid-October to early March) after leaf fall and before bud break. However, the UK’s maritime climate means that ground conditions are often not suitable and most commercial harvests are carried out in the spring, summer or autumn.

Harvesting is the single largest cost component of willow biomass production accounting for about 32 – 60% of costs over the life cycle of the crop (20 plus years).

Several ways of mechanical harvesting have been explored. The direct cut and chip method is most widely used in the UK. In the past, whole stem harvesters and baling systems have been available. Small scale growers also manually harvest with chainsaws or use forest excavators with tree shears.

Efforts to reduce harvesting costs by improving the performance and reliability of the harvesters and chip collection system are essential for the profitability of willow production.

Introduction

Willow is a short rotation woody crop that rapidly produces large amounts of biomass. The harvested willow biomass can be processed into renewable energy, heat, and other products such as livestock and poultry bedding, biochemicals, bio-packaging, and more. Willow is harvested in a three-to-four-year rotation cycle after establishment and can be harvested seven or more times before replanting. It requires minimal crop maintenance between harvests.

Harvesting is the single largest cost component of willow production, accounting for about 32 – 60% of costs over the life cycle of the crop (20 plus years). As such there should be efforts aimed at reducing the harvest cost by having reliable high performing harvest systems to improve the harvesting efficiency and increase the profitability of willow biomass production. One of the Biomass Feedstocks Innovation Programme projects (Net Zero Willow) is aiming to do this by producing a tracked harvester with integrated bunker.

Before planting an SRC plantation, the logistics of harvesting must be considered. For instance, it is important to create an efficient plantation design based on the harvesting method (mechanical or manual) and factor in headlands (unplanted areas around the edge of a crop field) to accommodate the efficient turning of machinery and reduce harvester downtime.

Timing of willow harvest

Willow harvesting should be carried out on a three-to-four-year rotation cycle. Current practice is to harvest three years after the initial planting. Previously, growth in the establishment year was cut back to promote coppicing. However, commercial experience suggested that this led to lots of immature plants being killed before they could properly establish.

Willow harvesting should be done during the dormant season in winter (mid-October to early March) after leaf fall and before bud break in early spring.

The ideal situation would be to harvest willow when the ground is frozen. This avoids excessive loads on the soil by the harvesting machines. However, such optimal conditions are hardly ever feasible in the UK’s maritime climate with mild winters.

However, harvesting windows are not exact. The timing can depend on several factors such as the yield of the crop, the soil conditions and the availability of harvesting contractors. Harvesting can be delayed for a year or two if the growth of the plant is poor due to drought or competition from weeds, insects, or pests. In some circumstances there is no choice but to delay harvesting until the following year especially if weather conditions are unsuitable. Experience suggests that harvesting in poor conditions leads to soil damage and erosion resulting from deep furrows forming in the field. It can also lead to additional costs borne by the contractor due to tyre punctures caused by slipping and sliding into previously harvested stools. Climate change is making the timing of harvests even more difficult.

Most commercial harvesting currently takes place in spring, summer or autumn. This is far from ideal as the woodchip will be contaminated with leaves, which increases the moisture and ash content and makes the biomass fuel more abrasive to boiler systems. Furthermore, the harvested plant biomass removed from the field deprives the soil of carbon transfer and nutrients recycled into the soil.

Harvesting Systems

There are various ways of harvesting willow involving either a single step or two-step method of harvesting. With the single step, the willow crop is cut directly from the stump and chipped in one operation. While with the two-step harvesting, the willow crop is first cut, stored, and naturally air-dried before later chipping and processing into the desired end product. In most situations mechanical harvesting is the only option. In small plantations (usually less than 3 hectares) it is logistically possible to manually harvest and remain economically viable.

Mechanical Harvesting

Mechanical harvesting is the only option for harvesting largescale willow plantations, where the large capacity of the machines can be fully utilized, and the high capital cost can be spread over large harvest volumes. Studies have shown that to increase profitability, it is essential to have machinery available that can produce high-quality wood chips at low cost and be easily managed during storage and transport. There are five contractors currently operating in the UK. They operate various modified forage harvesters that cut and chip willow in a single pass.

Cut and chip harvest system

With the cut and chip harvester, the willow plants are harvested in a single operation and directly chipped and transported to the end user or storage site. The harvester either pulls its own trailer to collect the harvested material or more usually uses a tractor-trailer combination, which travels alongside the harvester and receives the chips blown from the harvester. To optimise efficiency, the harvester downtime should be reduced by keeping the harvester moving and harvesting the willow crop on a continuing basis, while two or three tractors and trailers work in tandem to continuously collect the chips and move them to the load staging area or directly to the end user. The plantation design and staging area should be well laid out to facilitate machinery movement and turning at the end of the rows. Chips produced from the cut and chip harvester, however, have a high moisture content and may require further drying to reach lower moisture content for efficient thermal combustion into energy. Dry chips can attract higher prices from the consumer but this is generally offset by the requirement for additional handling, storage, and fuel costs required for direct drying.

Manual Harvesting

Manual harvesting involves the felling of the willow plants with a chainsaw or brush cutter and collecting the logs manually or with a tractor, followed by direct feeding of the logs into a chipper. Alternatively, the logs can be collected and stored and chipped later. Manual harvesting is labour intensive, requiring a minimum of two persons, and is best suited for harvesting small scale plantations, but is less costly and therefore an affordable option for small scale farmers who lack the resources to purchase expensive harvesting machinery. It can also be used in situations where it is the sole available option when commercial operated machinery is not available when needed, although it is less efficient and less productive compared to the use of mechanical harvesters (one report indicated that it takes on average 45 hours to manually harvest 1 hectare of willow containing about 18,000 plants). A study reported harvesting cost varying from €16.3 ha−1 to €23.2 ha−1, suggesting manual harvesting an affordable option for small scale farmers even though gross production rates are very low (0.10 – 0.11ha/h to cut and lay). Another study showed that manual harvesting exposes workers to noise, uncomfortable work postures, and high cardiovascular loads. This study suggested that motor manual harvesting operations should consider the compatibility of equipment and operational conditions to the workers undertaking such tasks.

It should be noted that manual harvesting results in the stool height rising as chainsaw operators do not always go to the base of the stems. This makes it almost impossible to revert back to the direct cut and chip method in the future.

Latest Technical Articles

Eucalyptus as a Biomass Crop

Key messages:

- Eucalyptus species display rapid growth characteristics, high water and nutrient-use efficiency, and have been identified as having great potential for use in short rotation forestry (SRF) or coppice (SRC) in the UK.

- Low temperatures and unseasonal temperature fluxes are the main limiting factor to Eucalyptus growth.

- Eucalyptus species and provenance must be selected and matched appropriately on a site-by-site basis.

Introduction

The Eucalyptus genus is native to Australia where species have adapted to grow under a wide range of climates and challenging environmental conditions. A number of Eucalyptus species have been identified as having great potential as a short rotation forestry (SRF) or coppice (SRC) species in the UK. Eucalyptus is suited to short rotation forestry due to its fast growth rate and high biomass yield, which can exceed that of other native species. When planted in favourable locations growth rate can be 2 – 3 m per year and can be harvested from 4-6 years onward. Based on an 8-10 year rotation, data from early UK trials identified yields in the range of 20-30 m3 ha/yr, on a bark-free basis, equivalent to 10-15 oven dry tonnes per hectare per year. Yields of up to 48 m3 ha/yr have been reported from a commercial plantation in Cornwall. Eucalyptus produces a high-density wood, with a net calorific value of 18 GJ t, which seasons quickly and is suitable for use as a biomass fuel or timber product.

Site Suitability

Low temperatures and unseasonal temperature fluxes are the main limiting factor to Eucalyptus growth. Frost damage can be a problem during establishment, but risk can be mitigated by proper species selection and silvicultural management.

In general, there is an inverse relationship between frost hardiness and growth rate. E. nitens, for example, displays exceptionally fast growth rate but is more susceptible to frost, this restricts its growth-range to southern Britain. Species such as E. glaucescens and E. gunnii are more cold- tolerant. Mountain-type E. coccifera and E. urnigera have been shown to perform well in exposed conditions and have been established successfully as far north as Moray in Scotland. Other species such as E. rodwayi are swamp varieties which are suited to wetter regions and ground conditions.

| Species | Growth rate | Frost hardiness |

| E. nitens | **** | * |

| E. denticulata | **** | ** |

| E. globulus ssp. Bicostata | **** | * |

| E. glaucescens | *** | *** |

| E. johnstonii | *** | ** |

| E. delegatensis | *** | * |

| E. regnans | *** | * |

| E. gunnii | ** | *** |

| E. coccifera | ** | ** |

| E. dalrympleana | ** | ** |

| E. urnigera | ** | ** |

| E. rodwayi | ** | ** |

A table listing some of the main species suitable for use in the UK, including indications of growth rate and frost hardiness is included below; adapted from a review of Eucalyptus in the British Isles.

Eucalyptus species and provenance must be selected and matched appropriately on a site-by site basis. Factors of water availability, elevation, likelihood of unseasonal frosts, soil type and light levels must all be considered.

Establishment

Ground can be prepared via traditional cultivation or planting using a no-till approach. Physical or chemical weed suppression is required post-planting. Alternatively, planting can also be performed through a geotextile membrane to suppress weeds.

Planting is performed from seedlings at stocking densities of between 1,600-2,500 stems per hectare at (2.5 x 2.5m – 2.0 x 2.0 m spacing). 2-3 ha is considered the minimum area for viable commercial production. Tree-shelters and stakes are generally required to protect young plants and support early growth. Due to rapid growth rates, close monitoring is essential for the first few years until trees successfully establish.

- E. dalrympleana, Devon, aged 14 months.

- E. denticulate, Devon, Aged 14 months.

The primary objective is to achieve canopy closure as soon as possible and create a suitable microclimate for trees to thrive. Mixed species stands, or planting with other tree species in shelterbelts, can improve resilience and offset risk. For example, more cold tolerant species can be included on exposed stand edges. Mixed-age stands can also reduce risk from frost damage and exposure by providing shelter for younger trees by providing a positive microclimate and protected environment. Staggered planting and harvesting can be performed to provide continuous self-supply or be adapted to suit farmland available to fit around core farm business and provide other benefits.

Eucalyptus light canopy can afford options for growth in the understory. This means stands are well suited to agroforestry use (silvo-arable/pastural) as well as in shelterbelts, riparian buffer strips and sight screens.

Management, pests and diseases

Leaf loss is a common sign of stress in Eucalyptus trees and should be watched out for. Few pests are currently prevalent in UK. Psyllids are a common infestation on establishing trees but generally have minimal impact. The leaf beetle, Paropsisterna selmani has posed problems in Ireland and eucalyptus gall wasp (Ophelimus maskelli) could pose a threat in the UK. Eucalypts have displayed good resistance to Phytophthora and other foliar pathogens. Young growth can be palatable to deer but the oils in the foliage deter extensive browsing of the foliage. Fencing may be required in areas where these animals are prevalent.

Harvesting

Harvesting is performed using conventional forestry methods. First thinning can be done from year 4-6. At higher stocking densities, and under suitable growing conditions, around 16 t ha can be expected at 1st thinning. Commercial data suggests an annual sustainable yield of around 40m3 ha yr can be achieved, producing consistent roundwood for chipping or firewood use from year 4-5 onward.

- Four-year-old E. nitens stand grown in Cornwall. Trees were 12m in height, 12cm average diameter (dbh)

- Logs produced from first thinning (year 4)

Coppicing – most Eucalypts will coppice well and their capability to do so also mitigates risk if damage to the main stem occurs due to frost or browsing. Coppicing can be performed from years 2–7 and stools will remain productive for 3-4 rotations of 4-8 years, after which the stool viability will drop.

If chipping wood: harvest time, storage conditions and moisture content of the chip needs careful consideration. Higher moisture content can lead to increased fungal growth (composting) in chip stack and under some conditions can also present a fire risk which needs to be accounted for in management of the chip.

Eucalyptus wood can retain higher concentrations of chlorine in the biomass which can cause corrosion in boiler systems if significant quantities are burned. However, this risk can be offset by biomass mixing or pre-treatment. There is also evidence chlorine content decreases with stand age.

Additional uses and benefits

- Eucalyptus foliage is widely used in floristry.

- Eucalyptus attracts pollinators.

- Eucalyptus honey production

- Volatile oils from foliage have potential for multiple applications in nutraceutical and pharmaceutical products such as antiseptic and anti-inflammatory products.

Summary of promising Eucalyptus species for SRF in the UK

|

|

|

|

Further information:

Forestry Commission – Grant funding for woodland

Forest Research – Wood fuel supply guidance