Hemp as a Biomass Crop

Take home messages:

- Industrial hemp has greater versatility and profitability than many other biomass crops like giant miscanthus, willow, poplar and switch grass.

- It yields high biomass (12- 15 t/ha of air-dried biomass) with minimum input of water, fertilizers and pesticides.

- The best applications for industrial hemp include co-production of hemp products like insulation material for buildings, hemp paper, textiles etc with biofuels.

- It is an excellent rotation crop that fits well with food and feed crops and improves the yield of the subsequent crops due to the beneficial effects of hemp on the soil like improving soil structure and reducing parasitic nematodes and fungi.

- The UK lags behind its European counterparts in hemp production due to the regulatory forces and unless changes to these regulations are made, farmers may be less attracted to the produce hemp.

Introduction

The conversion of biomass to biofuels has gained heightened interest due to the increasing demand for sustainable and eco-friendly sources of energy. Traditionally, biofuels have been produced from starchy or sugar crops such as corn, wheat, sugar beets and sugar cane. However, this gives rise to competition between food versus energy. Therefore, there is a need for dedicated non-food energy crops, especially those where the whole plant biomass can be used for energy production resulting in potentially higher land use efficiency. Moreover, if such crops could be fitted into a crop rotation system with food and feed crops land use efficiency can be further increased. Energy crops are projected to play a significant role in the future of bioenergy due to the paucity of biomass from forestry output and the scarcity of acceptable “waste” streams.

Industrial hemp (Cannabis sativa L.) is one of the oldest crops in the world traditionally grown for its fibre. Hemp fibre was the main fibre for maritime ropes and sails and was used extensively as a raw material for cordage and textiles. However, its production declined in the middle of the 19th century due to the disappearance of the sailing navy, competition from natural fibres like cotton and jute and later due to intensive development of synthetic fibres.

In the 1930s cultivation was forbidden in most Western countries and in North America due to its genetic closeness to marijuana which created a lot of confusion and social, political and moral controversies. The 1990s marked renewal of hemp cultivation for agricultural, industrial and scientific reasons throughout the world mainly due to increasing consideration of natural resources, energy conservation and biomass conversion to bioproducts and biofuels.

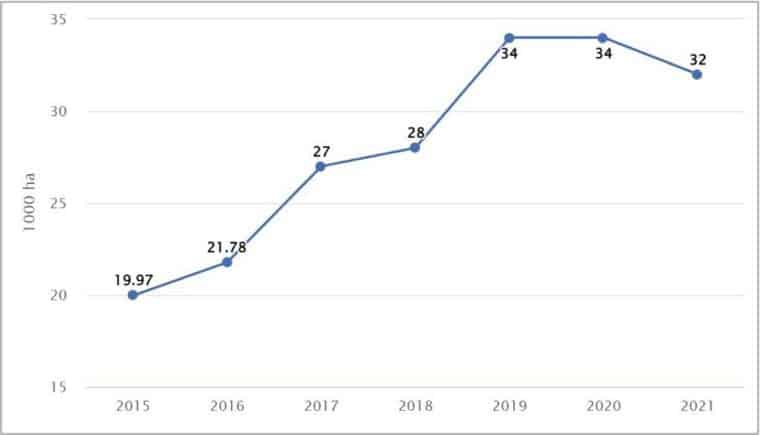

Since 1992, France, the Netherlands, England, Spain and Germany have passed legislation allowing for the commercial cultivation of industrial hemp. Two years later, Canada followed in the footsteps of the EU passing regulations that allowed farming of hemp. The area dedicated to hemp cultivation in the EU (fig 2) has increased significantly from 19,970 hectares (ha) in 2015 to 34,960 ha in 2019 (a 75% increase). In the same period, the production of hemp escalated 62.4% from 94,120 tonnes to 152,820 tonnes. France is the leading producer in Europe, accounting for more than 70% of EU production, followed by the Netherlands (10%) and Austria (4%).

Fig 2. EU land used for hemp Fig 2. EU land used for hemp cultivation from 2015- 2021cultivation from 2015- 2021

Recently there has been renewed interest in hemp as an insulating material as well as a feedstock for specialist paper. It is also an excellent rotational crop. It uses a fraction of the water needed to grow cotton, absorbs more carbon dioxide per hectare than other crops and most trees and its every part is beneficial. Its extensive root system improves soil structure and subsequent crops have less weed pressure. Studies in winter wheat crops grown after hemp have reported yield increases of 10-20%. This may be attributed to decreased parasitic nematodes and pathogenic fungi and reduction in soil water loss and soil erosion due to hemp growth.

Hemp is also highly efficient in ecological reconstruction and land reclamation owing to its phytoremediation capacity i.e its ability to remove heavy metals from the ground. Overtime it can remove heavy metals and other contaminating substances from the deeper layers of the soil as its root system develops. Finally, biochar produced from hemp for soil applications could potentially improve soil carbon sequestration and reduce greenhouse gas emissions.

Important factors in growing hemp for Energy

Soil and Climate

Hemp cultivars adapt well to a temperate climate therefore they can be farmed in most countries in Europe including UK. During the growing season, they require 200–300 mm of rainfall. The amount of rain that falls throughout the summer is less crucial for development than enough soil moisture. A strong tap root system effectively lessens the impact of a brief drought. As a result, seed germination can take up to 8–12 days at a soil temperature of 8–10oC. Young plants may withstand brief frosts of up to -6oC degrees. The duration of the day has a significant impact on how hemp develops. Hence, the recommended time for planting hemp for biomass is at the end of April.

A well-established soil that is nutrient- and organic-rich is necessary for hemp. The soil should have a pH that is neutral or slightly alkaline. A robust root system ensures that plants can absorb water and nutrients from the soil’s deeper layers. In crop rotations with a large proportion of cereals, hemp is a desirable preceding crop because it enhances the aggregative structure of the soil.

Tillage and Cultivar Selection

Hemp requires winter ploughing and spring tillage to prevent soil dryness. The amount of nutrients in the soil and the previous crop should be taken into consideration when deciding how much mineral fertiliser to apply before planting. The amounts of specific fertilisers are as follows: approximately 80 kg/ha of N, 50 kg/ha of P2O5, and 90 kg/ha of K2O. In general, hemp doesn’t need chemical pesticides or weed killers to control weeds, diseases, or pests because it has one of the intensive early growth rates of any agricultural crop. Hemp should be planted at a density of 40–50 kg/ha with a row spacing of 20–30 cm.

There are 75 varieties listed in the EU common catalogue of varieties of agricultural plant species. The main factors that influence the choice of the hemp variety include the suitability for growth in the region and the end product for which it is grown. Most cultivars of hemp are capable of yielding 12–15 t of air-dried mass per hectare genetic and breeding work is carried out to obtain new lines yielding over 20 t/ha of biomass with a high fibre and cellulose content and trace amounts of THC.

What makes hemp a potential bioenergy crop?

The demand for biomass for conversion to energy is rapidly increasing and is expected to accelerate in the coming years. Industrial hemp is valuable due to its high biomass and energy yield per hectare. Several studies have claimed that hemp could be used in energy production as a fuel source with no sulphur emissions either by direct combustion or converted into liquid fuels such as bioethanol. Hemp oil, which was traditionally used as lamp oil, can be used to produce renewable biofuels which emit less carbon monoxide on combustion to replace gasoline for diesel engines thus helping in relieving global warming.

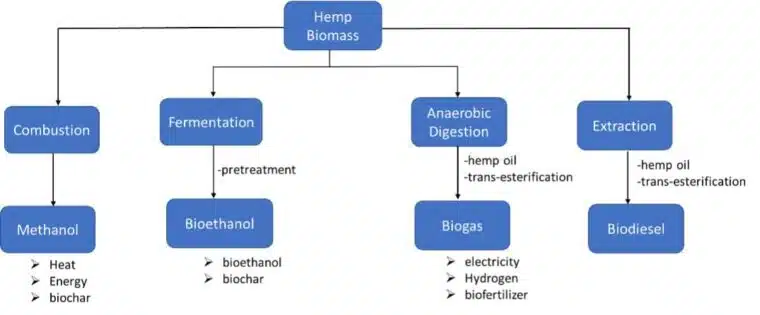

The whole plant can be used to make a variety of products in a biorefinery, including feedstock and biochemicals like succinic acid, heat from briquettes or pellets, electricity from baled biomass and vehicle fuels like biogas from anaerobic digestion or bioethanol from fermentation. In terms of biofuels, hemp can provide, biodiesel made from the pressed seed and bioethanol and methanol from the fermented stalk, all of which are clean renewable alternatives to petroleum-based fuels. The possible pathways for bioenergy production from hemp biomass are illustrated in figure 5.

Hemp is a rapidly growing plant that can withstand high planting density and its total biomass per hectare is similar to other energy crops like the giant miscanthus, poplar, switchgrass and willow. However, the significant advantage of hemp over other energy crops is that the concentration of digestible cellulose and hemicellulose is higher in hemp bast fibres. They contain 73-77% cellulose, 7-9% hemicelluloses, 2-6% lignin compared to 48%, 21-25% and 17-19% respectively in the hurd. On the other hand the cellulose and hemicellulose of hemp hurd are comparable to that in the stems of giant miscanthus, poplar, switch grass and willow (table 1). Notably, 20–30% of the stem biomass in hemp consists of high cellulose fibre, resulting in a higher ratio of digestible sugars to lignin in hemp than in other similar-yielding biofuel crops. These characteristics make hemp an above-average energy crop for some biochemical-based biofuel production and greenhouse gas mitigation applications.

Table 1. Fibre yield and composition of hemp compared to other proposed biomass crops.

| Crop | Biomass (Mg DM/ha/yr) | Cellulose (%) | Hemicellulose (%) | Lignin (%) |

| Hemp fibre | 7 – 34.0 | 73-77 | 7-9 | 2-6 |

| Hemp hurd | 34-48 | 21-25 | 17-19 | |

| Corn stover | 4.6 – 5.5 | 38 | 26 | 17 |

| Switchgrass | 5.4 – 34.6 | 28-37 | 23-27 | 15-18 |

| Giant miscanthus | 10.0 – 44.0 | 50-52 | 25-26 | 12-13 |

| Poplar | 7.7- 17.3 | 42-49 | 16-24 | 21-30 |

| Willow | 6.2-21.5 | 46-56 | 12-14 | 13-14 |

Fuel Quality of Hemp

The most important characteristics when evaluating any fuel are the calorific value, ash content, melting behaviour, physical handling characteristics, and any negative effects on heat exchanger corrosion or stack emissions. The following section assess the fuel quality of hemp. Comparison to other fuel crops is made where data is available.

Calorific value

This is the most important property of any fuel. Biomass from both the whole hemp plant as well the by-products (shives and straw) can be a good raw material for energy production. A study at the Teagasc biofuel laboratory reported that, provided hemp can be dried in the field to a moisture of 20%, its net calorific value is higher than many other forms of biomass and much higher compared to that of peat (table 2). Thus, hemp can be an excellent alternative to plants operating on peat fired energy. However, differences in gross caloric value are small.

Table 2. Gross and net caloric values of some biomass fuels.

| Material | Calorific value (MJ/kg) | Assumed moisture content (%) | |

| Gross | Net* | ||

| Hemp | 18.5 | 13.4 | 20 |

| Wood residues | 19.7 | 10.0 | 40 |

| Straw | 18.0 | 13.0 | 20 |

| Peat | 21.5 | 8.9 | 50 |

*heat available with no further drying and no recovery of latent heat

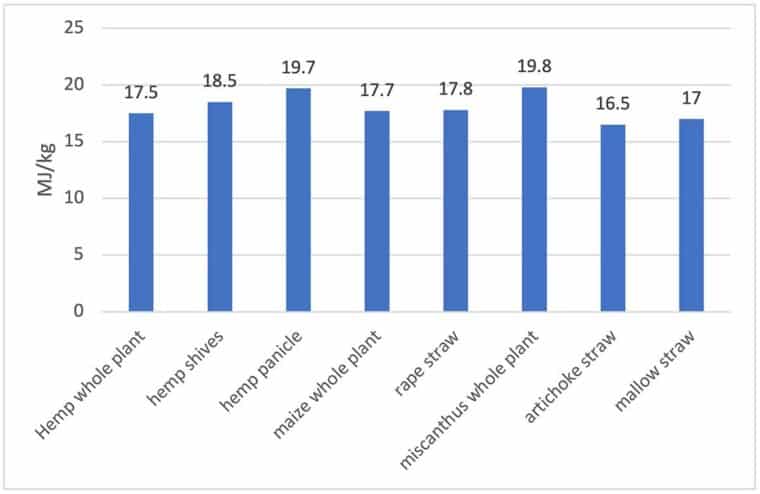

Another study reported the gross calorific values of hemp whole plant and by products compared to other biomass and found them to be comparable or better (fig 6). This study also reported hemp to be resilient to conditions of draught and the energy efficiency per hectare of hemp exposed to water shortage was 10% higher than that of maize under the same conditions confirming the suitability of industrial hemp for energy production.

Ash and Melting Point

The ash content of hemp samples reported in scientific literature varies between 3-4% which is much higher than wood but lower than peat and similar to many non-wood biomass materials. Hemp’s high ash content unavoidably extends boiler maintenance times and causes ash disposal issues but how much longer depends on the application. For instance, it might render the fuel unusable as a pellet feedstock for home heating stoves or boilers in urban areas, be anticipated to have little impact on the rural boiler market and be welcomed by generating stations already using peat with 6-7% ash.

The melting behaviour of ash is also crucial, particularly in applications requiring high combustion temperatures. Low melting temperatures can cause ash to clump together and obstruct grate openings and ash removal systems. The melting behaviour depends on the composition of ash but even with variations the calculated values for hemp ash melting point is higher than most other non-wood biomass. Therefore, under normal combustion conditions ash melting problems should not be an issue with hemp.

Corrosivity and Emissions

One of the major issues with non-wood material is the propensity of the fuel to corrode heat exchanger surfaces and is mainly a function of chlorine, potassium and sodium contents of the material. Hemp has low Cl and Na levels, while its K content is higher than that of wood but similar to that of many straws. Hemp typically has superior qualities to cereal straw, which is effectively burned in power plants in Denmark and the UK, and boilers and Combined Heat Power (CHP) plants in Denmark.

Stack emissions (gases released into the air from boiler stack, chimneys or diesel generator set stack) depend on the plant design, operational factors as well as fuel composition. A fuel with high volatile content and low in sulphur, chlorine, potassium and heavy metals generally tend to have low stack emissions. Hemp stems contain <80% volatile compounds higher than most other plant biomass and moderate levels of S, Cl and K. Although no excessive heavy metals have been measured in hemp, but as hemp as the ability to take up heavy metals from the soil, emissions may be a problem if hemp is grown on contaminated soils.

Profitability analysis

The main factors to consider when determining profitability include crop yields, production costs, energy costs, and the support available for renewable energy. The following section analyses the profitability of hemp grown for energy based on these factors.

Yield

Hemp’s ability to produce significant biomass yields with relatively little water input is one of its main advantages. Hemp requires less water than many other crops, including alfalfa and maize, and may produce 15 t of dry matter with only 250–400 mm of water when grown using modern production techniques. The ambient temperature is another factor that influences hemp development; it can be grown most successfully between the ranges of 13 and 22 °C. As hemp has natural defences against disease and insect attack, growing it requires just a little amount of biocides. These factors make hemp relatively inexpensive to grow.

A 3-year study in Ireland showed that under Irish climatic conditions early sowing has a big impact on yield. Furthermore, seed rate can be chosen to optimize yield and seed cost without any concern about fibre quality. This study also reported that a seeding rate of 30kg/ha gave the highest yields. The study concluded that a harvested yield of 11 t/ha of dry matter, corresponding to about 13.7 t/ha at 20% moisture is achievable and profitable.

Harvesting

The cutting and windrowing procedure is expensive and has a significant impact on field losses, in-field drying, and baling efficiency. There is a need to develop new harvesting machine designs that enable the co-production of improved hemp products, such as high-quality seed and straw which may in turn help to improve the viability of industrial hemp production.

Economics of growing hemp

Hemp grown for energy must be profitable for farmer to produce biomass for energy. In order to ensure encouraging prices for the finished product based on contracts, lower production costs are required. The low-cost production of fibre, seeds, or essential oil for technical uses can slightly increase the profitability of hemp produced for energy. The residual biomass (straw and shives) can subsequently be sold as briquettes for use in the generation of energy.

Hemp production varies greatly on an annual basis, and therefore the profitability of growing hemp inevitably changes as well. In Canada, one of the top hemp producers in the world, the revenue from hemp production is estimated to be $510/acre for fibre, $400/acre for grain, and $580/acre for both fibre and grain hemp production. This is comparable to the suggested returns from a US study.

Another US study which compared hemp with kenaf, switch grass and sorghum found that hemp generated the greatest revenue of these four crops, yielding $2632/ha ($2462/ha from grain and $170/ha from ethanol) compared to $908 for kenaf, 4803/ha for switchgrass and $1725 for sorghum when used for coproduction of ethanol and grain, though hemp had lower biomass yield. These values include the yield and value of hemp and sorghum grain as well as the growing cost for each type of biomass. One study looked at the profitability of hemp by pricing it as an energy commodity with the same price as oil. It found that industrial hemp had a net yearly profit of between €2000 to €3500/ha, which was higher than the earnings from both canola and sugar beetroot. Using organic fertilisers also enhanced profits, though less significantly than for canola and sugar beetroot.

In EU countries, farmers who grow hemp are eligible for area-based direct payments under the Common Agricultural Policy (CAP) provided the hemp variety being cultivated has THC (Tetrahydrocannabinol, the main psychoactive compound in marijuana) content of no more than 0.3% and is listed in the EU common catalogue of varieties of agricultural plant species. In the UK very little hemp farming has taken place in the recent years, in spite of a long hemp farming history, and the nation today falls behind its European rivals significantly. Only 20 farmers in the UK currently cultivate hemp on an area of 800 hectares. The main cause of this is the onerous regulations. Industrial hemp cultivation is legal in the UK with a licence since it is considered a “special purpose” under the Misuse of Drugs Act of 1971 (MDA). As a result, hemp farmers must adhere to strict guidelines for the licensing of controlled substances.

Conclusion

Hemp has great potential to become a promising commodity crop for producing both biofuels and value-added products. It is an excellent rotation crop that fits well with food and feed crops and improves the yield of the subsequent crops due to the beneficial effects of hemp on the soil. The best applications for industrial hemp include co-production of hemp products with biofuels. Its high yield, higher ratio of cellulose to hemicellulose and digestible sugars to lignin and economics of production give it a competitive advantage over other biomass crops like giant miscanthus, willow, poplar and switch grass.

To promote the development of hemp as a biomass crop in the UK, changes to the regulations which require licensing to produce hemp are required. Subsidies for investments in processing facilities and equipment would greatly increase the viability of hemp in existing crop cycles in the grasslands, where hemp biochar can be co-fired with coal to reduce emissions. Hemp producers can benefit from investment in processing equipment that can valorise many potential products from hemp.